We’ve got bran flakes and muesli a-plenty, we’ve got coarse and fine oats galore. You want the jumbo size? Sure! We’ve got everything.

A common concern when buying various oat products is ‘How do these differ from one another?’. Not to fear, for we are here to clear up any apprehension you might have about whether or not some of these products are the same and why not.

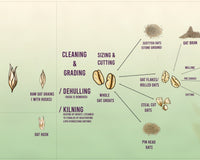

How Oats Are Made

Origin

Let's start from the beginning. Oats come from a plant known as Avena Sativa, a type of grass grown specifically for its cereal grain seed. When the plant is mature and ready to be harvested the seeds of the Avena Sativa plant are collected and this is where the oat journey begins.

Harvest & Processing

At this point in time, the seeds are known as ‘Oat florets’. After the florets have been harvested they are gathered, loaded onto trays and spray washed with a high-intensity water spray. This helps remove any foreign debris that may be present in the harvest, this process may be repeated a few times.

Once the florets have been adequately cleansed they are put through a large separator. This helps sort the florets by size. The larger florets are used for oatmeal and other food products whilst the ones of smaller size are diverted for use in animal feed.

Next, the oat florets are graded based on density and size. To perform this graders judge the oat florets by width and are then put through a second separator composed of perforated cylinders.

After the florets have been graded, they go into the hulling process. Human beings cannot digest oat hulls. Thus, the florets are put through rotating discs that move at different speeds depending on the size of the oat to remove its exterior.

(At this point in the process the florets are now known as groats (dehusked oats and grains). This is the oat grain in its most whole, intact form. The husk has been removed, but other than that, the bran, endosperm, and germ remain intact.)

After this process what is left is a mix of hulls, groats, florets, and broken groats. This mixture is then re-introduced to the discs, further removing hulls and smaller particulates. Once this is done, the groats are placed on tilted tables that rock back and forth further separating the florets and groats. The groats continue along the process, and any remaining florets get sent back to the discs.

The final step in processing is known as drying or kilning. During this process, the groats are put into long vertical cylinders where they are blasted with air and steam to increase the temperature. Radiant heat is then added to get rid of any moisture remaining in the oats whilst simultaneously killing any bacteria or inactive yeast that is left. At this point, the groats are able to be sold as they are, or they can be refined further.

Refining

This is the part where all lovely oat derived products are born. The next few steps in the refining process have to do with sizing, cutting, milling and rolling. Once the groats have been dried they are run through a cutting machine where sharp knives slice them up into flakes if they require being cut down into smaller sizes. After this the oats are rolled flat between steel rollers, turning them into flakes. At this stage in the process, some of the oats lose the outer layer of the seed known as the bran, the outer layer of the groat. The final stage of the refinement process is grinding, where the oats are milled into flour.

The Difference Between Different Types of Oats

Steel Cut Oats

If groats are cut into two or three pieces with a sharp steel blade, you get steel-cut oats. This gives them a bit of a chewier texture than the whole oat groat, taking between 20-30 minutes to cook. They cook quicker than oat groats, as the water can more easily penetrate the smaller pieces. Steel-cut oats can be made on the stovetop, in a slow cooker, or in an Instant Pot. Steel-cut oats are also sometimes known as Irish oatmeal.

Pinhead Oats

Pinhead oats are a coarse form of oatmeal where oat groats have been chopped into two or three pinhead-sized bits. It is nutritious because it still has the bran attached, it can be made into traditional porridge however, it takes about an hour to cook.

Scottish Oats

The groats may also be refined by grinding. Instead of cutting the groats with a metal blade, the scots traditionally stone-grind them creating broken bits with varying sizes. Some say this results in a creamier porridge than their steel cut counterparts. They cook in about 10 minutes on the stovetop and can also be cooked in the microwave.

Rolled Oats / Old-Fashioned Oats / Porridge Oats

Rolled oats, also known as regular or old-fashioned oats are created by steaming and then rolling out the groats into flakes. The steaming process helps to stabilise the oats by deactivating the lipid hydrolysing enzymes. This helps the oats stay fresh for longer, whilst creating a larger surface area ultimately allowing the oats to be cooked faster. By far the most popular form of the oat, rolled oats can be used in various applications. Cooked on the stovetop as oatmeal, making overnight oats, used as an ingredient in pancakes, baked goods, muesli, granola, smoothies, the list goes on. Rolled oats are best cooked on the stovetop and typically take between 5-10 minutes to cook.

Jumbo Oats

Jumbo oats simply go through the process of being steamed and then rolled. No cutting is necessary.

Quick Oats

Quick oats are a variation of rolled oats, after being steamed they are also rolled to be thinner. This increases their surface area thus, lessening its cooking time.

Quick oats tend to cook in about 1-3 minutes in the microwave however, they do have a mushier texture compared to regular rolled oats. They are great for baked goods, quick breakfasts, granola, overnight oats, energy bites, etc.

Instant Oats

Instant oats are the most processed version of the rolled oat. After being steamed and rolled they are usually pre-cooked and dried before being sliced into even smaller pieces. These are the quickest oats for cooking and only need a quick zap in the microwave or a soak in hot water to be ready to eat. Instant oat products oftentimes contain unnecessary sugars and additives, be sure to check your product labels. Instant oats like quick oats have a mushier texture when compared to regular rolled oats.

Oat Bran

Oat bran is sometimes a by product of oat manufacturing. The bran is the outer layer of the oat groat. Although the bran is not a whole grain it is still highly nutritious and rich in fibre. When Oats are being refined further they tend to lose the bran when they are refined further from being steel-cut. It can be used as a supplement in a way, a topping on cereal, as a hot porridge on its own, or mixed into baked goods to increase fibre content.

Oat Flour

The final and most refined form of oats is oat flour. It is nothing more than finely ground rolled oats. It is popularly used to thicken products or used in baked goods.

Conclusion

Hopefully, our little section on the processing of oats has helped shed some light on the ins and outs of what your oats really are and how they came to be. Be it porridge oats, toasted oats, coarse pinhead oatmeal, fine pinhead oatmeal, or oat bran it will now be much clearer what it is exactly that you’re buying. At Wholefood Earth we’ve got your back and also just about all that is necessary to fulfil all your oatmeal needs.